Showing all 5 results

Manufactured in Australia, Worldpoly's tracked fusion machines are built for high performance. With lightning service and spare parts support, machinery rated to 60+ degrees and a PLC built for harsh environments. It's not rocket science, just next-level engineering.

Packed with the latest technology and features, PolyForce tracked fusion machines are over engineered to exceed the needs of your operators and operations. Supported by a team that prides itself in delivering next level training, support and service. But that's what you get from a company with over 60 years experience in the poly pipe industry.

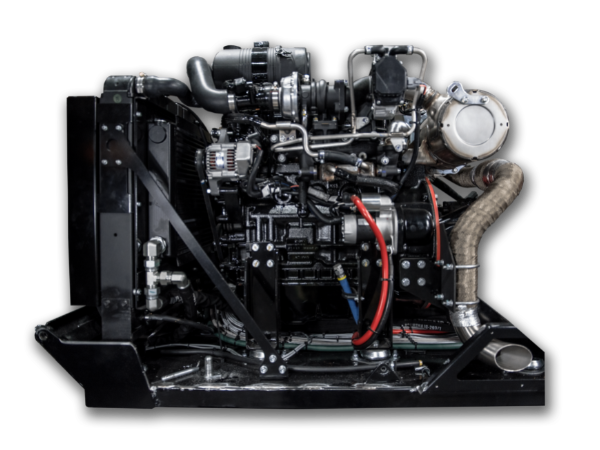

Get outstanding run time from an 1800RPM low-noise Yanmar 4 cylinder engine.

Ready to perform fusion all day and night for you and your team with sheer efficiency. Combine that with a top-end Meccalte 3 phase 18kVa alternator which is driven hydraulically from its’ own system, and mounted on heavy duty dampeners.

Unlike other OEM's, Worldpoly puts safety first with world class features. Two-handed operation and no operator man-entry provides intrinsically safe operation. Emergency stop buttons located at all operating areas with smart safety relays monitoring for activation (& failure) and wiring faults. Cordless remote control and data-logging are standard.

Built with a high strength chassis and wide powerful tracks, the PolyForce makes any terrain look easy. When you're choosing a fusion machine, you need the right mix of tough and quality components for your operations. Not one aspect has been overlooked, from hands-free smart clamps to innovative facing tool and heating plate, HDPE has never been so easy.

Unlike other OEM's, Worldpoly puts safety first with world class features. Emergency stop buttons located at all operating areas with smart safety relays monitoring for activation (& failure) and wiring faults. The engine control system is completely protected from electrical surges in the event of emergency shut-downs. A buzzer and safety beacon provides audible and visual safety measures when the machine is used for specific operations.

Built with a high strength chassis and the widest tracks available of any fusion machine on the market, the PolyForce makes any terrain look easy. Because when you're choosing a fusion machine, you need the right mix of tough and quality components for your operations. Unlike other OEM's, Worldpoly guarantees every component and manufacturing element. We're more than confident this machine will deliver when you need it most. Enquire about the pinnacle of fusion technology today.

Quality fusion is the centre piece of any Worldpoly machine. An automatic program adapts to pipe size and conditions to optimise overall and target parameters. With manual and automatic weld modes, the PolyForce delivers quality you can rely on. Not one aspect has been overlooked, from smart clamps to innovative facing tool and heating plate, HDPE has never been so easy.

Showing all 5 results

The PolyForce range can handle a wide variety of HDPE pipe diameters, from our PolyForce630i Tracked (Link) having capacity from 250mm to 630mm to our PolyForce1000i Tracked (link) able to weld from 500mm to 1000mm.

Our entire PolyForce range is covered under a genuine 3-year international warranty, which includes every aspect of the machine, even electronics and pumps. No matter what the issue, we cover the warranty rather than sending you to the original part manufacturer – after all, we were the ones who decided to use those components. Worldpoly is leading the way with butt welding machine warranties (link).

Safety is the foundation of every Worldpoly tracked butt welding machine. Our team takes pride in Australian engineered and manufactured machinery, with the original operating program written by Bosch Rexroth (link external).

Some of our safety features include:

Original components are locally sourced, making your nightmare of operational downtime a thing of the past. Worldpoly’s team respond immediately to all spare parts requirements, with one of the fastest capabilities to deliver spares anywhere in the world.

Fitted with high-power as-required hydraulic cooling, the PolyForce range can operate in ambient temperatures well above 50 degrees Celsius, use screens which can withstand 70 degrees easily, and PLCs as used in underground rock drills. All components are selected as being fit for purpose in the environment we know you’ll take our machines, so we're not going to be making excuses when you tell us where you’re welding.

We’ve covered that thanks to years in the Pilbara (Western Australia), and so long as you do normal maintenance won’t be blaming you for that.

Supporting poly welders in over 120 countries.