Showing all 3 results

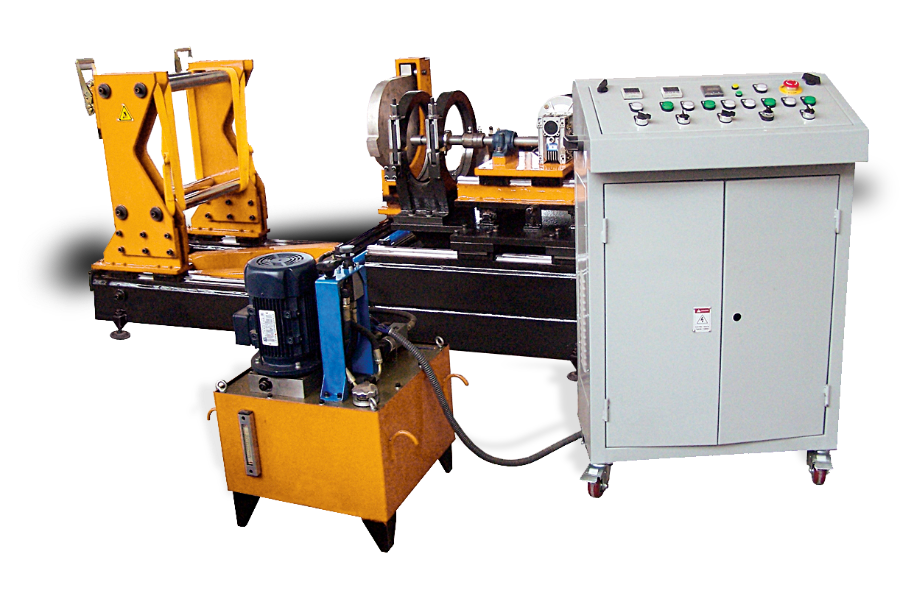

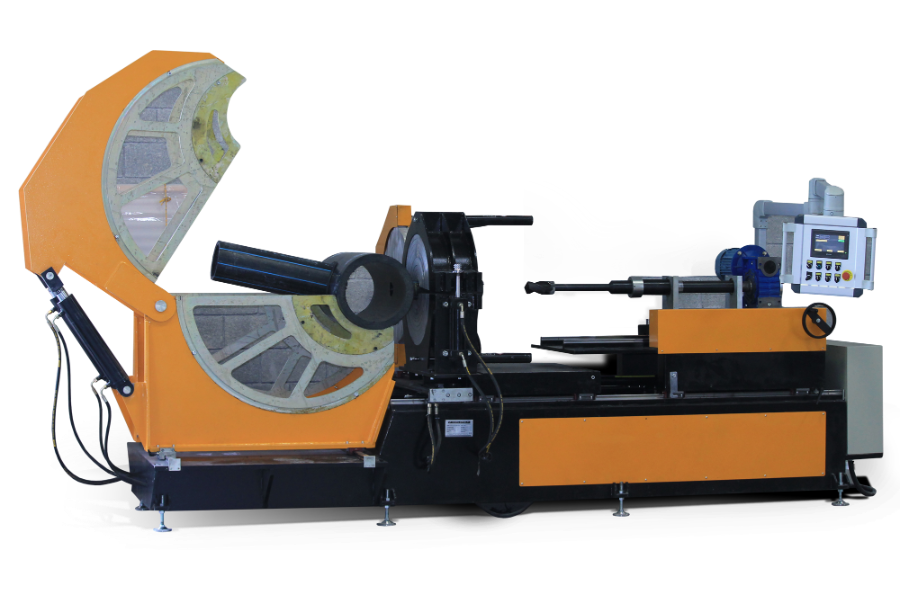

Hydraulically operated saddle fusion machines for the production of reducing tees. Worldpoly offers machinery for sidewall fusion of HDPE pipes from 63mm (2”) up to 1200mm (48”).

Worldpoly saddle fusion machines produce durable reducing tees and manifolds for all combinations of main and lateral pipes. The latest technology ensures equipment meets the highest level of requirements for modern production lines. If you need high-quality sidewall fusion, talk to our team about a PolySaddle for your operations.

Reducing tees and manifolds are important aspects of PE pipelines. The PolySaddle is designed for operation by one person, incorporating a hydraulic heating plate and loading system. Make pipe production easy for you and your team when you choose the latest in sidewall fusion machinery.

The PolySaddle range offers 90 degree fusion of HDPE pipe onto segments up to 50% larger than the original pipe. This applies to all combinations of main and lateral pipes from 63mm (2") up to 1200mm (48") OD. At Worldpoly, outstanding fusion isn't the only way you'll stand out to your customers.

Showing all 3 results

Saddle fusion (also known as sidewall fusion) allows for the welding of a smaller HDPE pipe at 90 degrees onto a larger pipe, thereby creating a reducing tee. To do this, the pipe is held in the machine at 90 degrees to the centre line of the machine, and the smaller pipe is fixed to the welding arm. A special radiused heating plate, with ‘male’ and ‘female’ sides is used to heat the pipe in preparation for the join. The ‘female’ side will melt the weld area on the main pipe, while the ‘male’ side melts the end of the smaller diameter pipe. The heating plate is removed, and the machine pushes the pipe ends together under a controlled temperate, time and pressure. It is important to note, the outlet diameter cannot be greater than 50% of the diameter of the main pipe.

Worldpoly manufacture saddle fusion machines for all combinations of main and lateral pipes from 63mm (2”) up to 1200mm (48”).

Supporting poly welders in over 120 countries.