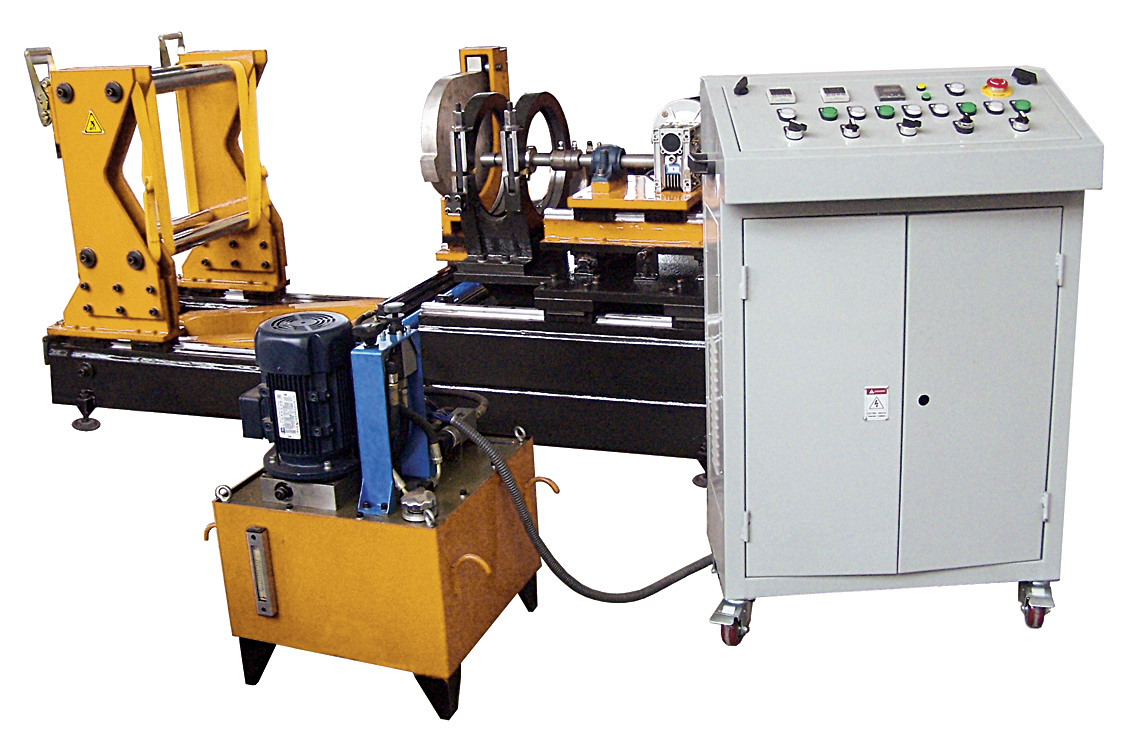

PolySaddle630/24

Hydraulically operated saddle fusion machine for the production of 90-degree reducing tees from standard PE pipe sections. Capacity 315 to 630mm OD (12" to 24") main pipe / 63 to 315mm (2" to 12") branch pipe, where branch pipe must not exceed 50% of

Hydraulically operated saddle fusion machine for the production of 90-degree reducing tees from standard PE pipe sections. Capacity 315 to 630mm OD (12" to 24") main pipe / 63 to 315mm (2" to 12") branch pipe, where branch pipe must not exceed 50% of the main diameter. Machine is constructed to allow operation by one person, incorporating main pipe clamp, branch pipe clamps, hydraulically removed heating plate with curved elements and integrated hole saw for final removal of pipe coupon.

Read More GET QUOTE

RELIABLE

Worldpoly machines operate with far less downtime than you've become used to.

Technical Specifications

General

| Main pipe range 315, 355, 400, 450, 500, 560 & 630mm / 12", 14", 16", 18", 20", 22" & 24". |

| Optional heating saddles and hole saws required for each main / outlet combination. |

| Hydraulically removed heating plate with Teflon coated radius attachments. |

| Hydraulic loading system for main pipe. |

| Count-down timer for heating and cooling times (to be set by operator). |

| Control panel with electro-hydraulic controls. |

| Note: When producing saddle fusion reducing tees, outlet diameter should be no greater than 50% of main diameter. |

| Specifications are subject to change without notice. Please reconfirm at time of order placement. |

Hydraulic

| Cylinder area: 12.56cm² |

Electric

| 400 volt 3 phase 50 Hz (11.3 kw 18 A). Optional 60 Hz US voltage also available. |

Options

| 90 degree branch pipe range 63, 90, 110, 160, 180, 200, 225, 250, 280 & 315mm / 2", 3", 4", 6", 8", 10" & 12". |