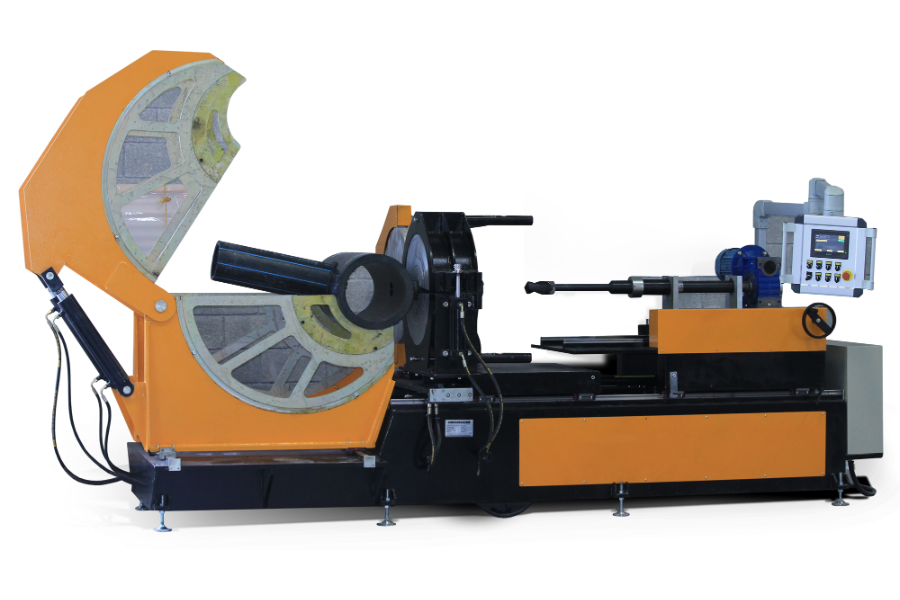

PolySaddle1200/48

Hydraulically operated saddle fusion machine for the production of 90-degree reducing tees from standard PE pipe sections. Capacity 315 to 1200mm / 12" to 48" main pipe, 63 to 630mm / 2" to 24"" branch pipe. Machine is constructed to allow operation

Hydraulically operated saddle fusion machine for the production of 90-degree reducing tees from standard PE pipe sections. Capacity 315 to 1200mm / 12" to 48" main pipe, 63 to 630mm / 2" to 24"" branch pipe. Machine is constructed to allow operation by one person, incorporating main pipe clamp, branch pipe clamps, hydraulically removed heating plate with curved elements and integrated hole saw for final removal of pipe coupon.

Read More GET QUOTE

RELIABLE

Worldpoly machines operate with far less downtime than you've become used to.