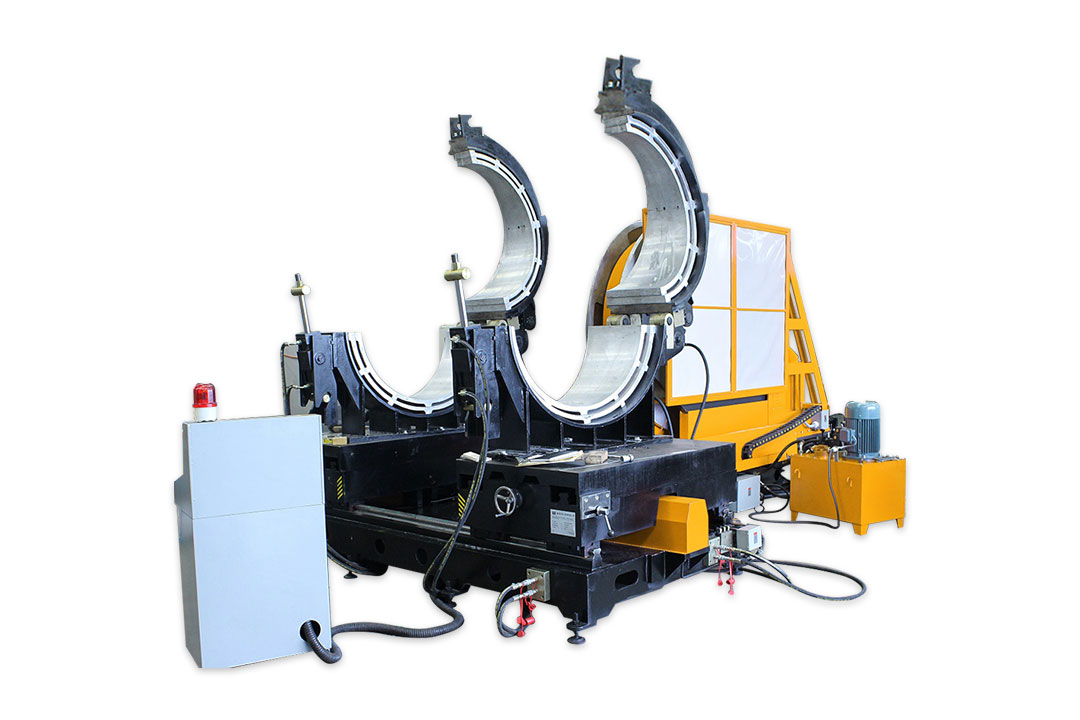

PolyWorkshop48i HF

Hydraulically operated CNC controlled workshop machine for the butt-welding of pipes and fittings in HDPE. Optional pivoting clamps allow for the fabrication of fittings having different radii. Available are hydraulic open/close/locking main clam

Hydraulically operated CNC controlled workshop machine for the butt-welding of pipes and fittings in HDPE. Optional pivoting clamps allow for the fabrication of fittings having different radii. Available are hydraulic open/close/locking main clamps and insert liners required to produce 24" to 48" segment welded bends, manual open/close/locking mains clamps and insert liners required to produce 24" to 48" segment welded 90 degree tees and crosses, and optional main clamps to produce branch tees and true-wyes 24" to 48". Please note that unlike others, this machine produces ALL fittings in ALL diameters within the range. Welding is performed at variable force. CNC touch-screen control of welding operations and integral 20,000+ weld data logger are standard.

Read More GET QUOTE

RELIABLE

Worldpoly machines operate with far less downtime than you've become used to.

Technical Specifications

General

| Welding range 24" to 32" DR 5 to DR 32, 36" DR 7.4 to 32, 42" DR 9 to 32, 48" DR 11 to 32 |

| CNC touch-screen control of welding operations and integral data logger are standard. |

| Welding operations are at both high (ASTM) interface force and low (ISO, POP 003, DVS) low force |

| Hydraulic open/close/locking of bend, tee and cross main clamps |

| Specifications subject to change without notice. Please confirm at time of order confirmation. |