900mm Reducing Liners

For North American Machines

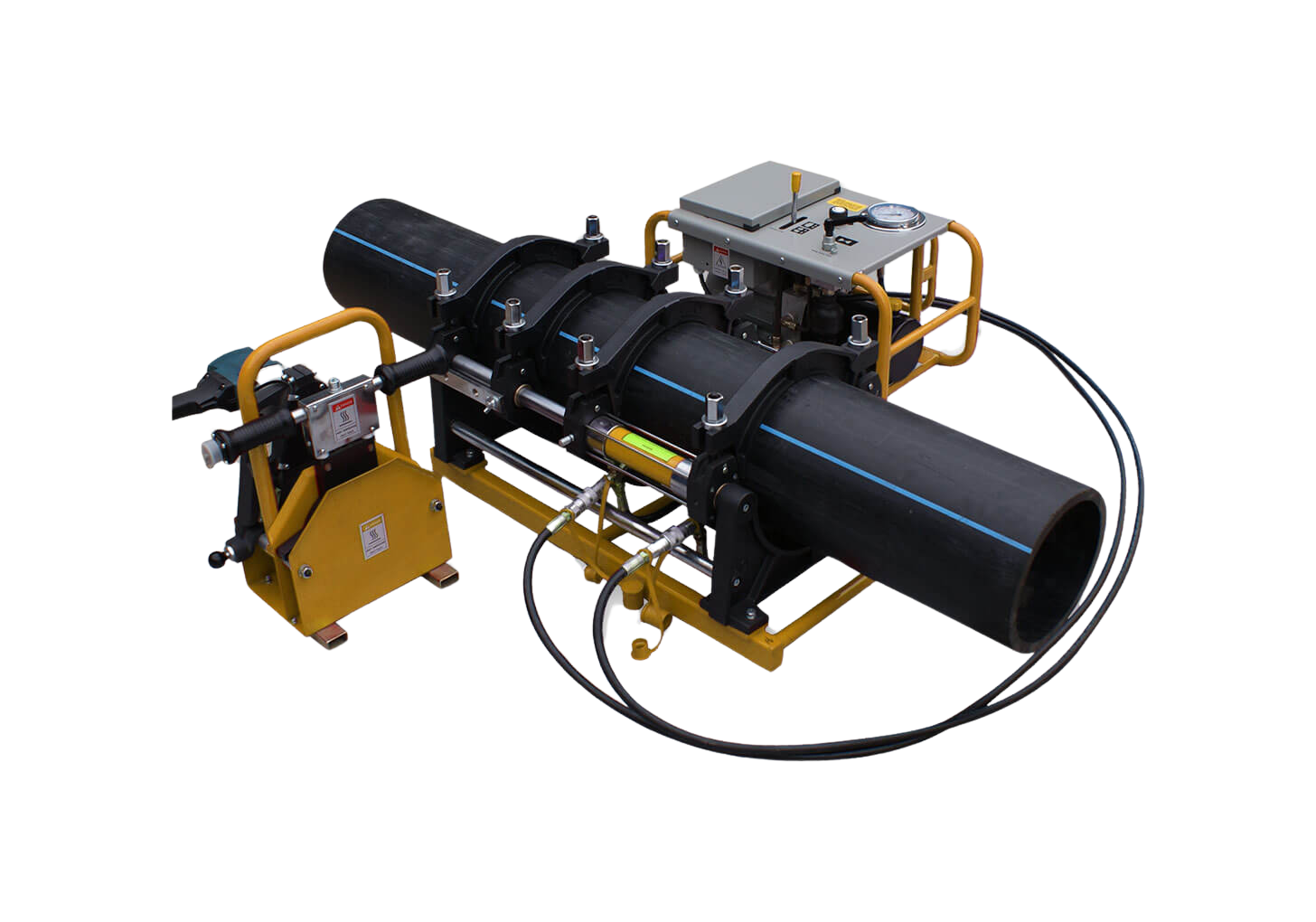

A leading Australian manufacturer of high-quality butt welding machines. worldpoly offers a complete range of low and high-pressure butt fusion machines for HDPE pipe from 40mm (2") up to 3000mm (120") OD.

Designed and engineered right here in Australia, worldpoly butt-welding machines have consistently provided our customers with many years of trouble-free welding. Intuitive and simple to use yet feature packed to make you more profitable through less downtime and more welds per day. Fully backed by a team who know butt welding and HDPE deeply, you know you’ll be getting the best support and the best value for your hard-earned dollar. Don't forget, worldpoly also keeps a full range of spare parts in Australia!

These premium machines are Australian engineered and designed for welding at the worksite or in the factory. Our high-quality pressure-cast aluminium castings means lower weight while still maintaining strength and performance, particularly by providing extra strength when welding out-of-round pipe. Significantly increased force is available for drag when welding pipe strings, or on difficult sites. Our machines have proven time and time again that they go the distance and weld when you want, where and when you want it. Our 50 plus years’ experience in designing and using polyethylene pipe welding machines, and our high rate of return customers, means we have the unique ability to understand our customers needs. worldpoly customers know we look after them and their machines, and we support them to get the job done.

Unlike others, when you buy a butt-welding machine from us, we sell you the facing tool, heating plate, stub device and all clamp liners specified for your machine. The hydraulic unit; which is an integral part of the machine, is included (not required with the PolyBasic160LF). All our hydraulic units have been tested in the harsh Australian environment and will stand the test of time. We keep a comprehensive store of parts for all worldpoly field butt welding machines in Australia, and our Australian based support team is armed with the knowledge and expertise to answer any questions you might have in any of ten languages.

With worldpoly machines, you can weld between clamps three and four for tees, bends and manifold work. If you need to keep records, most of our machines are prewired for data logging. On worldpoly CNC (computer numerical controlled) machines this integrated control ensures correct welding procedures including temperature, time, and pressure functions, and with on-board data logging for every weld. Low force and high force variants of most machines are available, so you can easily get the machine that is best for your job. In some circumstances, a high force machine (3.2 times more pressure than a low force machine) can save over an hour of cooling on your welds when compared to the same low force machine.

900mm Reducing Liners

For North American Machines

Supporting poly welders in over 120 countries.