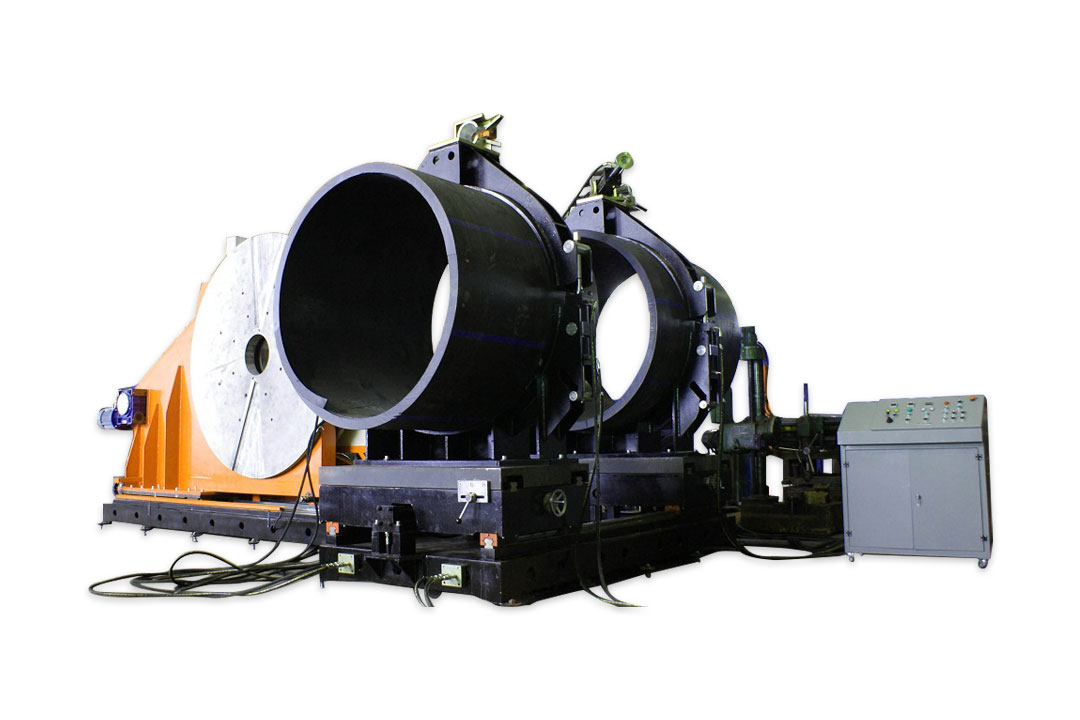

PolyWorkshop63i

Hydraulically operated CNC controlled workshop machine for the butt-welding of pipes and fittings in HDPE. Pivoting clamps allow for the fabrication of fittings having different radii. Optional main clamps are available to produce elbows, equal tees

Hydraulically operated CNC controlled workshop machine for the butt-welding of pipes and fittings in HDPE. Pivoting clamps allow for the fabrication of fittings having different radii. Optional main clamps are available to produce elbows, equal tees, crosses, branch tees 45' and 60' and true-wyes from 32" to 63" IPS. DIPS clamps are also available within this range. Welding operations are carried out at variable interface pressures using either the console or tablet control including integral 20,000+ weld data logger. Please note that unlike many, this machine is capable of producing the entire range of fittings across all diameters.

Read More GET QUOTE

RELIABLE

Worldpoly machines operate with far less downtime than you've become used to.