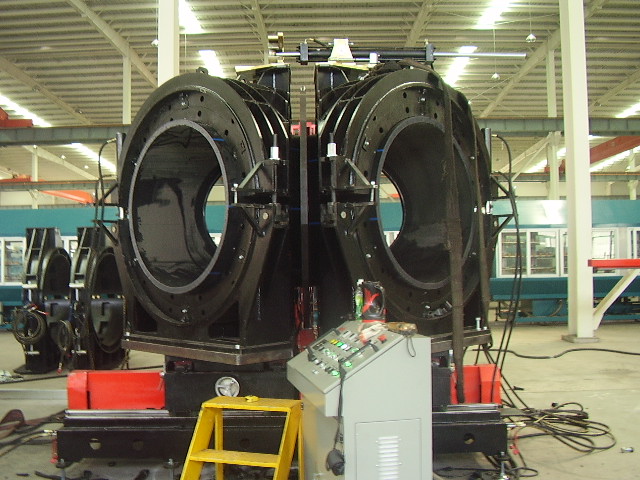

PolyWorkshop2000i

Hydraulically operated workshop machine for the butt welding of pipes and fittings in HDPE.

CNC control provides correct welding parameters, while on-board data logger saves quality control information.

optional clamps allow for the fabrication of

Hydraulically operated workshop machine for the butt welding of pipes and fittings in HDPE.

CNC control provides correct welding parameters, while on-board data logger saves quality control information.

optional clamps allow for the fabrication of segmented bends of different radii, equal square tees and crosses, equal y-branch tees of 45 and 60 degrees. Capacity 1200mm to 2000mm OD bends, 1200mm to 2000mm equal tees and crosses, and 1200mm to 2000mm 45 and 60 degree equal wye-branch tees.

Welding is carried out at variable interface force.

Please note that unlike many, this machine is capable of producing the entire range of fittings across all diameters.

Read More

GET QUOTE